Marelcom has developed controllers for years. From the concept to creating the scheme and layout of the printed circuit board, we create everything in-house. Our development department are master coders at C, C++, C#, HTML, Javascript or PHP.

If required, we will accompany you to EMC/ESD certification tests. Our expertise also covers motor and capacitive controls.

It’s also our pleasure to support you with the integration and commissioning of TFT displays, which entails complex requirements. The development of testing and programming units to be manufactured is also one of our strengths.

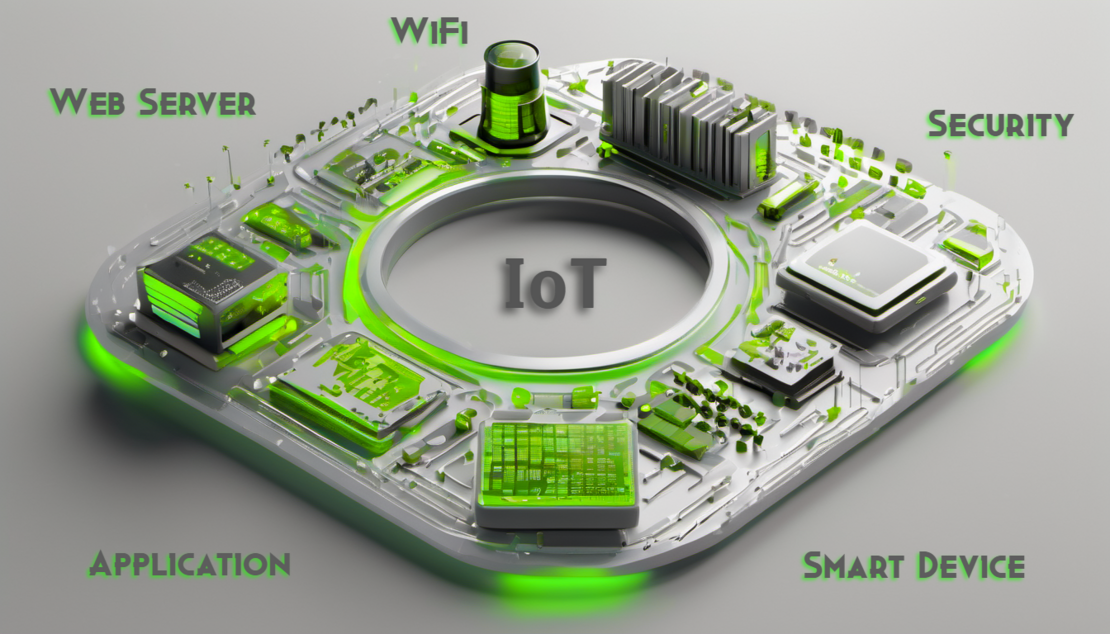

Discover the world of the Internet of Things (IoT) with Marelcom AG, your trusted partner for innovative solutions. Our customized IoT solutions enable you to efficiently control and monitoring of your environment. With modern technologies such as sensor-based data collection, cloud integration, and real-time analytics, we provide precise and scalable systems. From smart home applications to industrial IoT optimization, we are here to help you successfully implement your project. Our solutions support common IoT protocols such as MQTT and CoAP and ensure maximum security through encryption and authentication mechanisms. Let us shape the future together and explore the possibilities of IoT with Marelcom AG!

Accessing the device's statistical data currently requires physical presence at the device's location due to two main methods:

1. Physical Connection: The device must be physically opened and connected to a PC via a service connector.

2. On-Device Display: Alternatively, the data can be viewed directly on the device's display.

Proposed Solution:

To eliminate the need for physical presence, the device can be connected to the internet. This would enable remote access to the statistical data.

A WiFi module is required in the device.

Additional software is required to transfer the desired data to the WiFi module and make it available via a web server or to forward it to a specific web server.

The data can either be read and manipulated wirelessly from the device on site, or the device can be connected to the internet to send the data to a cloud. In this way, the manufacturer has the data available in real time.

In addition, the firmware can be updated wirelessly.

When a device is accessible over the Internet, it must be ensured that it does not represent a security vulnerability for the entire local network.

If the device has a security vulnerability, an attacker could access the local network and the devices in it via this device.

This must be prevented under all circumstances.

WiFi module

It is necessary to implement the data exchange between the microcontroller (uP) and the WiFi module. The associated effort varies from low to significant depending on the amount and type of data to be transmitted.

Creating a website to display the data:

Variant 1:

Configuring a web server

Variant 2:

Implementing data encryption

Configuring a cloud

Transimitting data to the cloud.

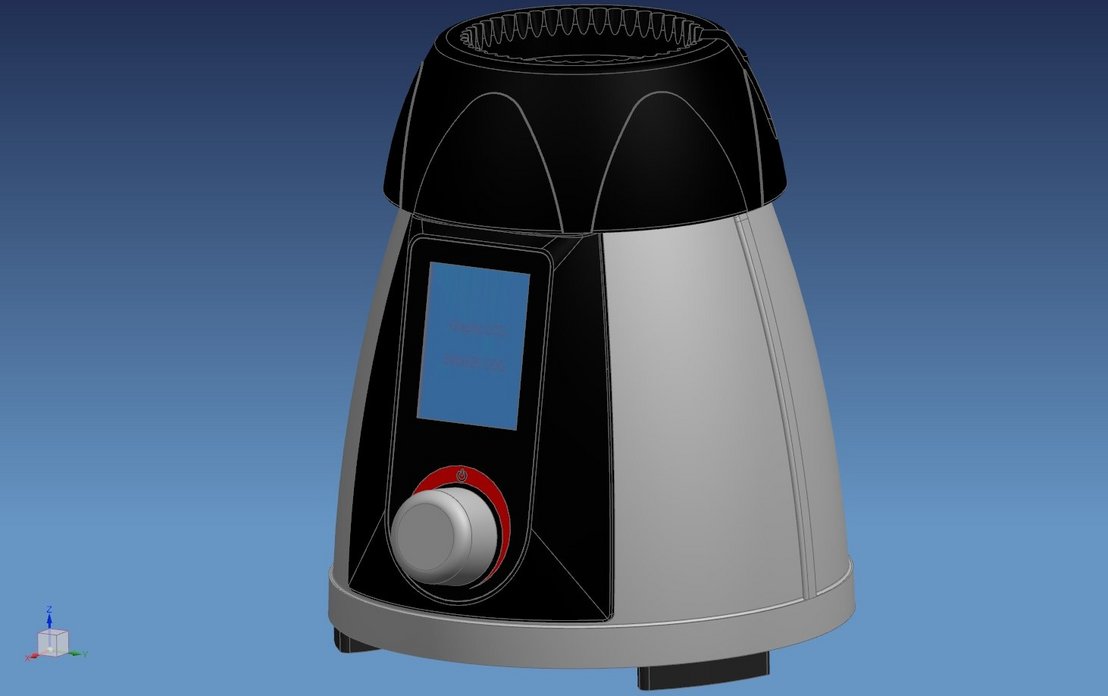

As an injection molded parts and injection molding tools manufacturer, we know the designing phase of your product is important. This is where the wheat is separated from the chaff and the properties of the future product are determined. Taking into account the production methods, the material and product application, we then design and create your customised plastic injection parts.

Your design specification is our starting point toward the development process. Working closely with you, we build your personalised products in 3D, and then ready them for production and development. With mold-flow studies, we are present in the entire process, from construction to the finished product. Customers benefit from our many years of experience and our competitive prices.